FACILITY & PROCESS

Production Process

-

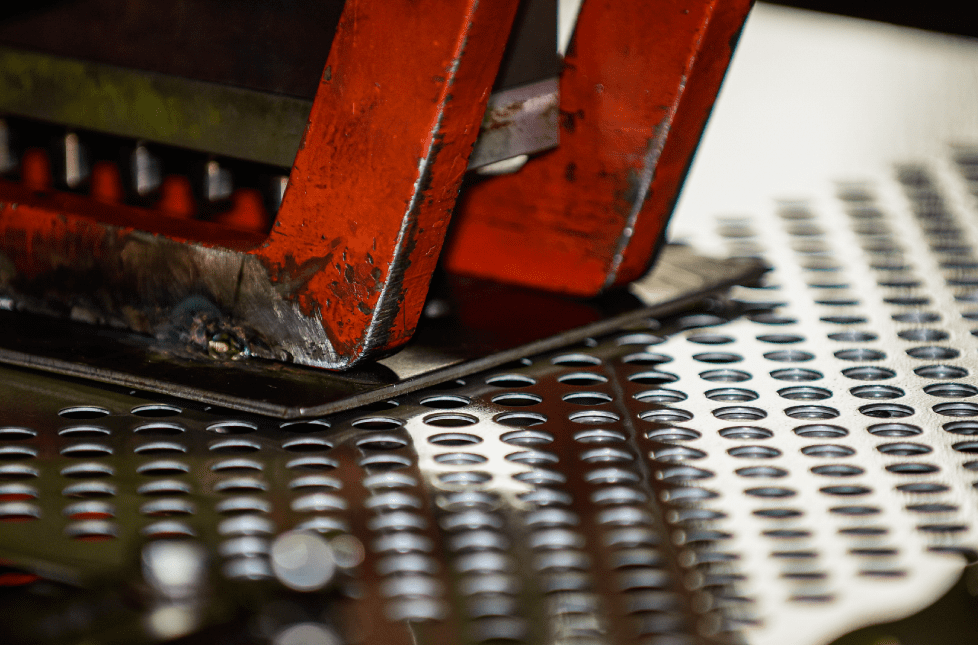

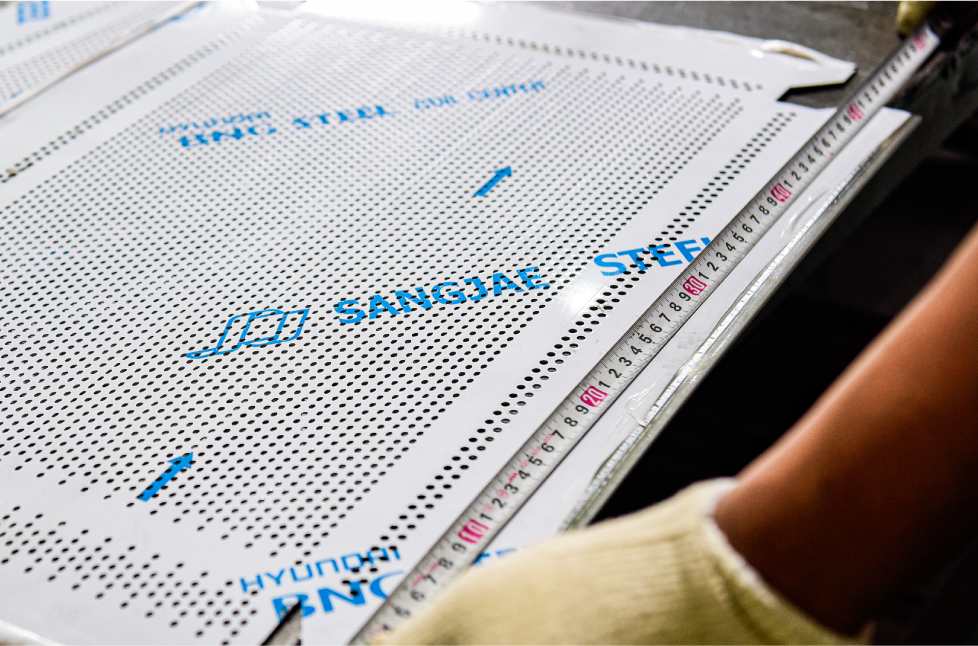

Perforation

In order to improve the precision and quality of punching, we have been developing automation of punching machines since 2002, making perfect products without defects.

-

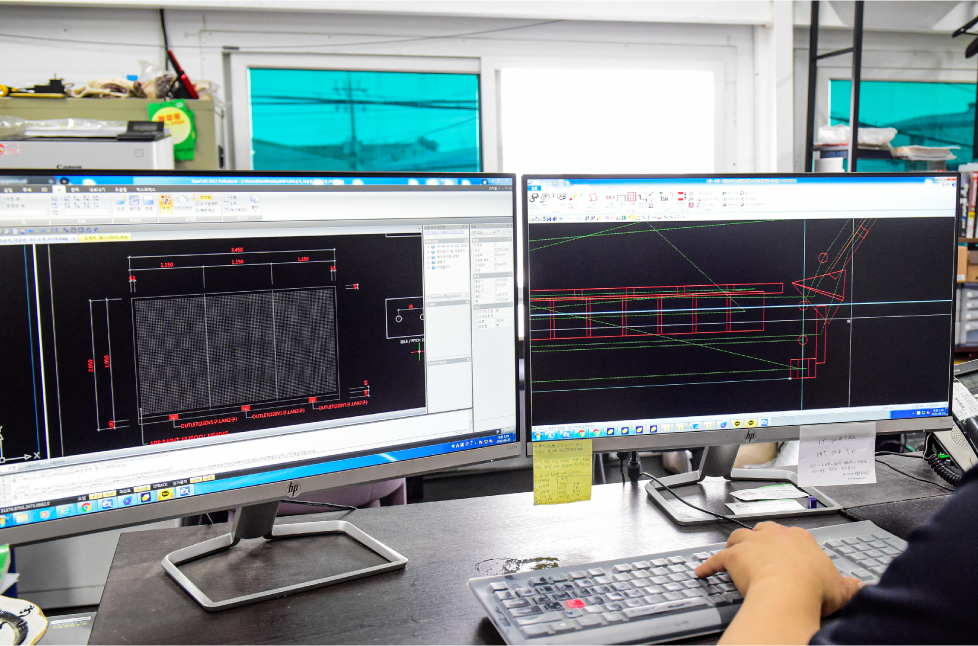

CAD/CAM

In 2005, the CAD/CAM system was introduced and the existing system was significantly strengthened. 2DCAD/CAM LANTEK's 2x LANTEK 3DCAD is designed based on "Solidworks". The accumulated data is managed by the server and data can be retrieved at any time.

A CAD system that supports various formats is also one of Taeyang's strengths. -

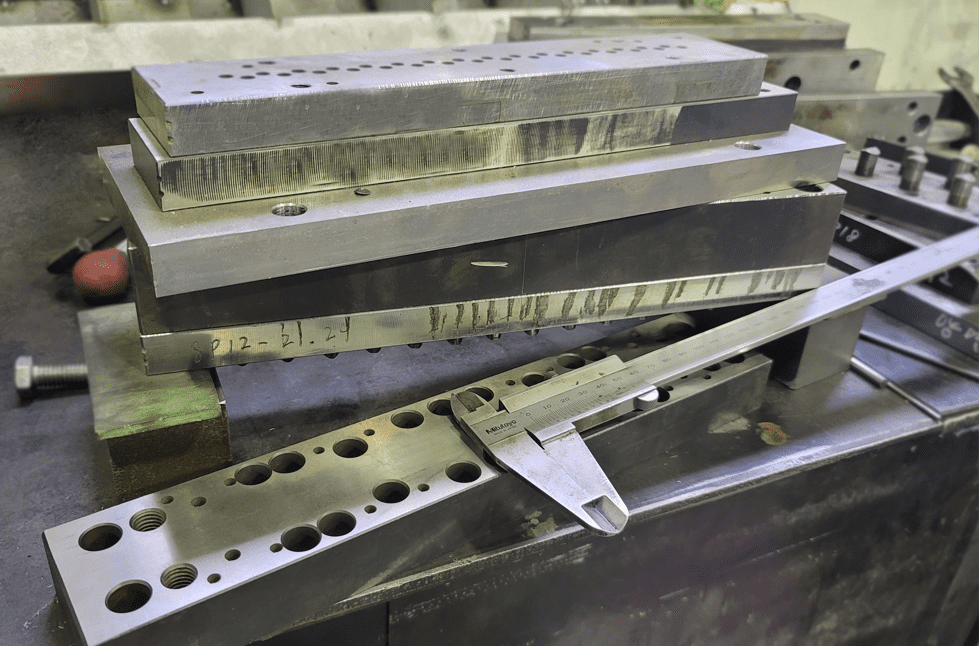

NCT/Laser/

ProcessingCAD/CAM process distribution, NC programmed products are pre-inspected in the development stage and delivered to the machining department.

At the machining site, the required quantity is processed with NCT according to the machining guidelines. -

Bending

Pre-machined finished products are converted to bending (bending). By utilizing the data extracted from the CAD/CAM process and utilizing complex bending data, machining with fewer mistakes is realized.

-

Welding

Welding processing of various materials is supported. In addition to general welding methods, we also weld color steel sheets including PO steel sheets.

-

Assembly

Assembling the rivets from the case.

In consultation with the manufacturer at the design stage, depending on the strength of the product, we assemble by welding rivets or a combination of the two methods. -

Final inspection/

shipmentThe finished product in the assembly process is delivered after a final inspection by the factory quality control department.

In the process, we always strive to provide the best products by thoroughly checking light including quality production.